The Chinaplas exhibition, Asia’s largest plastics industry fair took place from May 21st to 24th 2019 in Guangzhou. The event, which is held alternately in the southern Chinese Metropolis and Shanghai exhibits plastics material, machines and accessories and is considered the far east equivalent to the German K fair.

The fair is divided in two main branches, where one is formed by the chemicals and raw materials sector, while the other is covering equipment like injection molding and extrusion machines, automation and auxiliary devices.

The material branch of Thermoplastics, Duroplastics and Elastomers featured additives, pigments & masterbatches, composite & high performance materials, semi manufactured goods and the relatively new field of biodegradable plastics. Altogether more than 1000 exhibitors contributed to the show’s diversity in the raw materials sector.

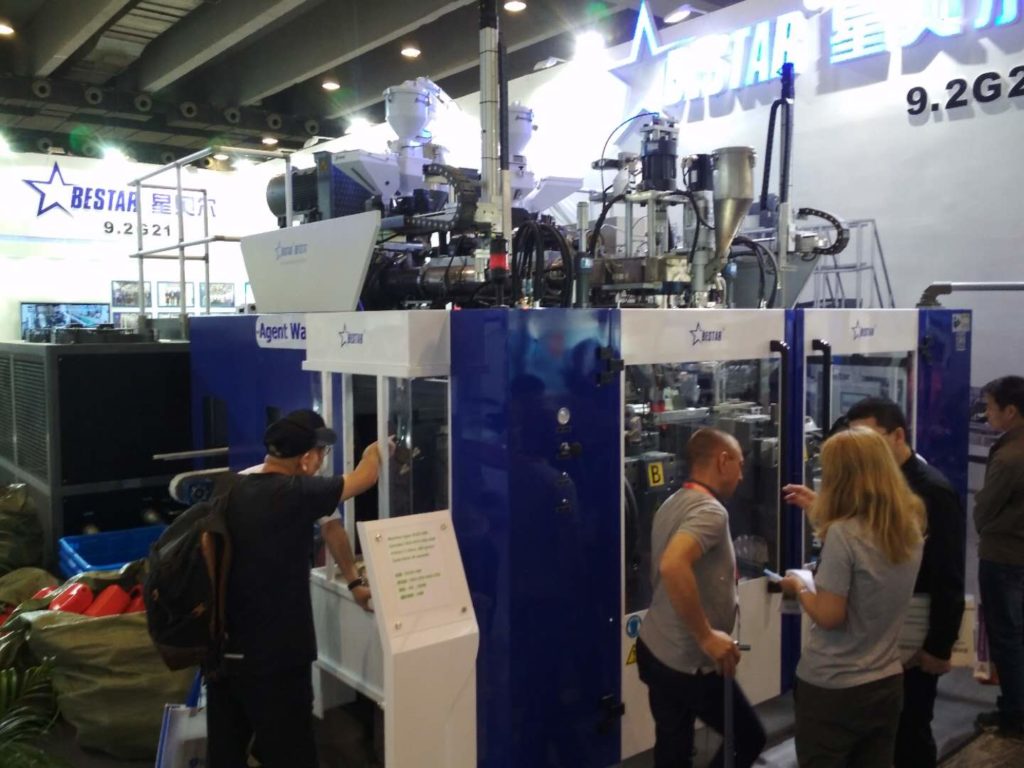

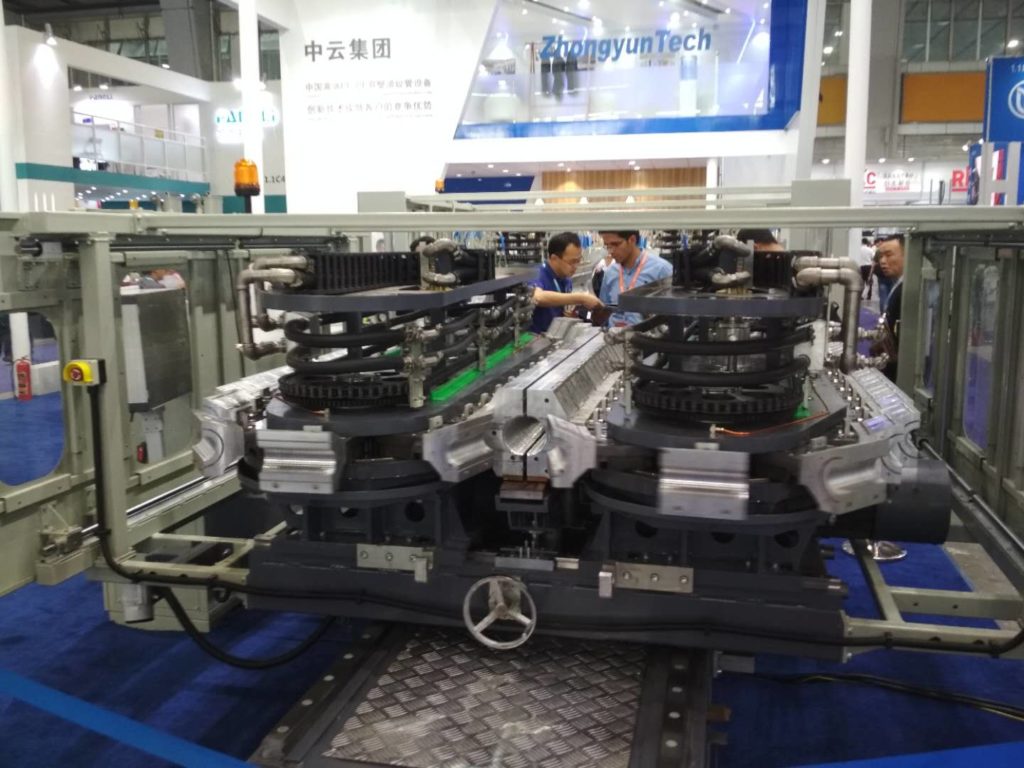

The machines and equipment sector mainly covered the area of tools, extrusion machines, injection molding technology, film manufacturing, elastomer processing, plastic packing, auxiliary and test devices, additive manufacturing as well as recycling technology. Over 3800 items where put on display for altogether more than 160,000 show visitors. Among the manufacturer’s countries of origin were China, Japan, Taiwan, Korea, Great Britain, France, Germany, Austria, Italy, Switzerland and the US.

The exhibition, which this year took place for the 33rd time declared Circular Economy one of its leading topics, so there was a specific emphasis on recycling technology, methods of waste reduction and biodegradable plastics. In terms of recycling, there was a spotlight on separating, washing, drying and pelletizing.

A further main subject was again Industry 4.0 – Factory of the Future. Among many Smart Factory solutions that were displayed by numerous exhibitors there were also two dedicated seminars from the ample event portfolio.

In the field of film technology, light conducting foils, high-speed vacuum thermoforming and 5-layer blow extrusion are some of the presented innovations particularly worth mentioning.

Some injection molding machine makers displayed their all-electronic versions which have advantage over conventional machines with respect to emissions and energy consumption. A continuous trend is the increasing operation of robots at the mold, for instance when placing components like in-mold labels or inserts, or picking and placing the molded products.

Among the numerous extruder and compounding machine solutions there were special modifications and variations like multiple layer extrusion heads, ERE technology and various laboratory extruders. Further extrusion machines on display covered medical, precision and corrugated hoses.

Alongside other innovations, waste recovery solutions with improved efficiency and highly reproducable and accurate granule characteristics were presented in the area of production recycling.

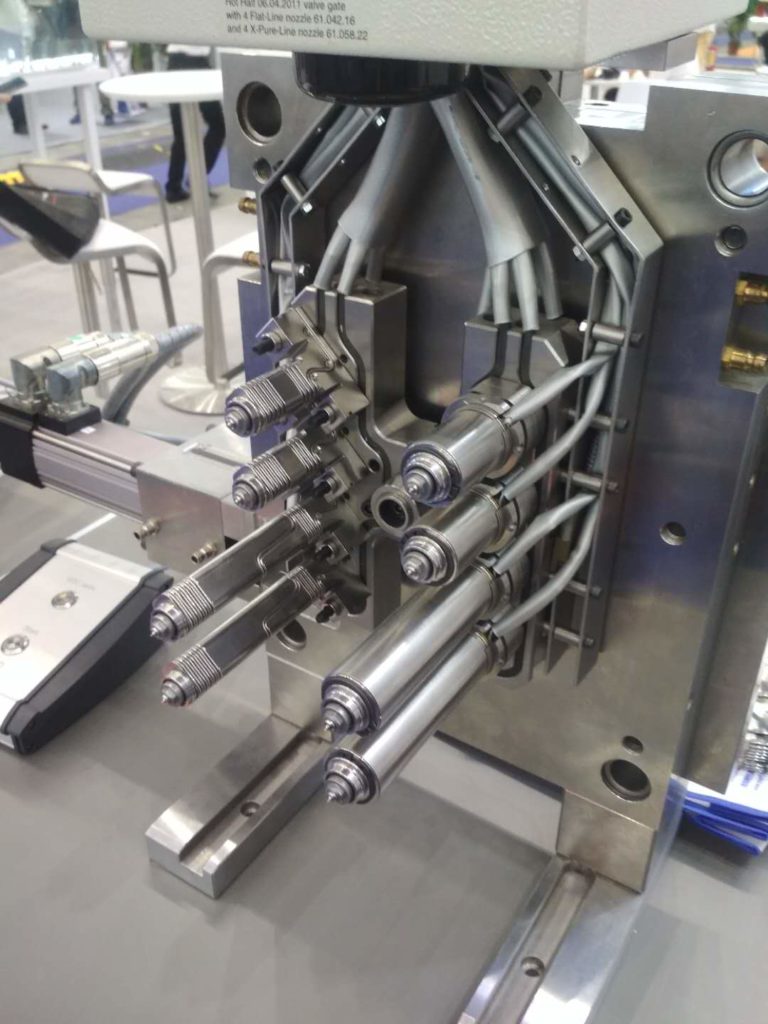

For tools technology and auxiliary devices, innovative solutions were presented for such items as slides, inserts, cores, ejectors, lifters, vacuum evacuation and hot runners. Other groups of auxiliary products featured were for example high performance dehumidifiers as well as electrostatic and optical sorting and separating systems.

This year the event series Tech Talk was mainly dedicated to thermoplastic elastomers in automotive, long fiber processing, in-mold labeling, precision extrusion and 3D technology. Further topics were TPE bonding, green additives, medical 3D printing and high performance flexible packaging solutions.