This year’s International Machinery Manufacturing Industry fare in Shenzhen Futian ended on Sunday after an eventful 4 days of exhibition. 110,000 sqm of the Convention and Exhibition center in the center of the Metropolis hosted the event for the last time as it will to move to the Bao’an district’s exhibition ground close to the airport in 2020.

We’ve been on the spot to take a look around.

Over 1100 participating companies and more than 130,000 visitors turned the venue into a buzz of activity, covering industries such as integrated technology & robotics, automation equipment, smart logistics and machine vision.

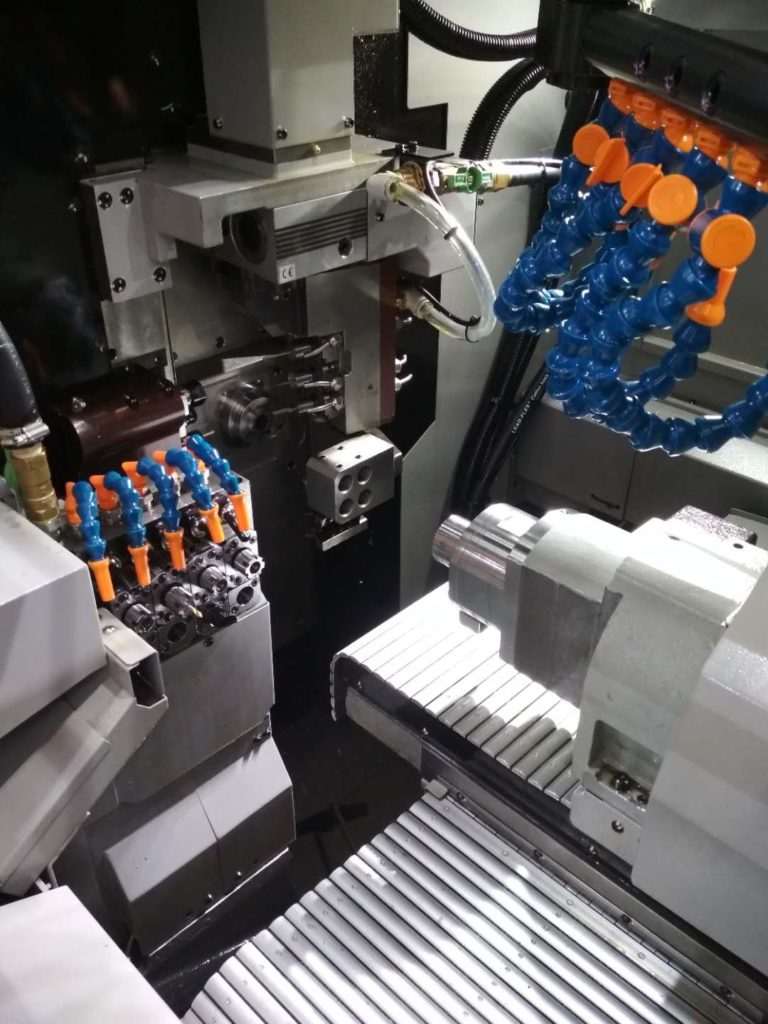

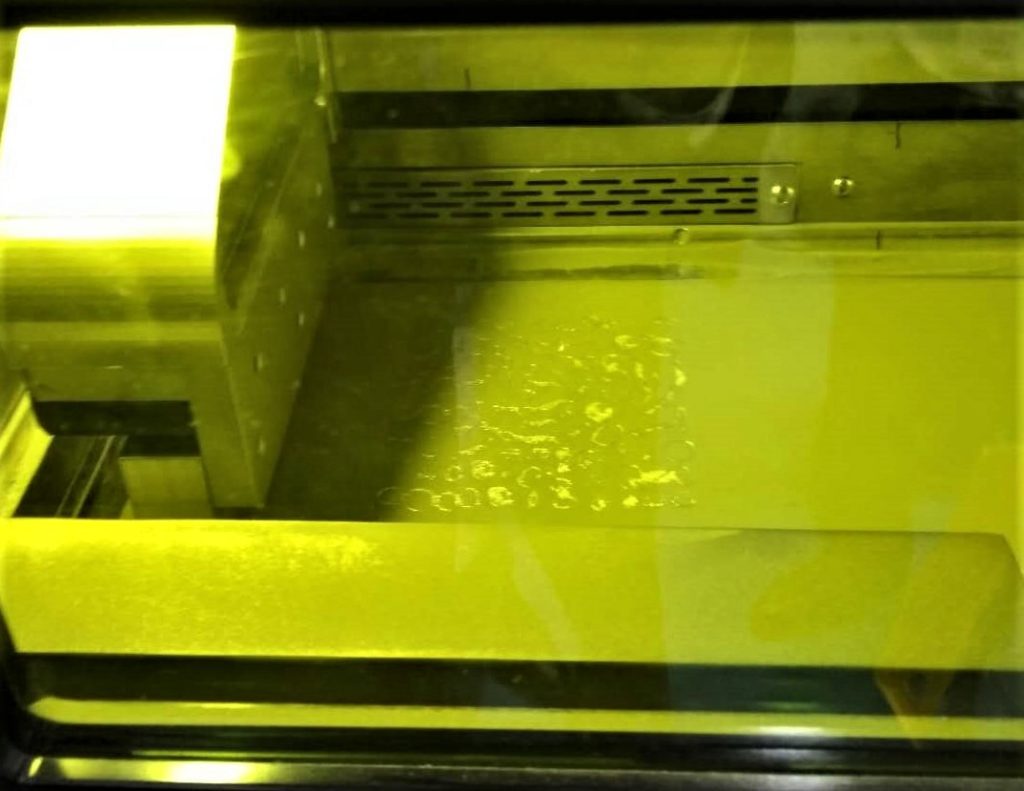

Hall 1 in the location’s center was hosting the wide range of metal-cutting machining technology, both from global players like Siemens, Fanuc or Tsugami and local competitors alike. The variety of machines included classical machining centers of all sizes and axis configurations, grinding machinery, laser cutting as well as more recent trends such as additive machining, e.g. selective laser melting & sintering.

Metal forming technology was the main feature of halls 2 and 3: classical sheet metal brakes, stamping and drawing machines, most of which numerically controlled, and further sheet processing equipment. Among the most well known brands Han’s Laser, Trumpf, Mitsubishi and MAZAK presented their products here.

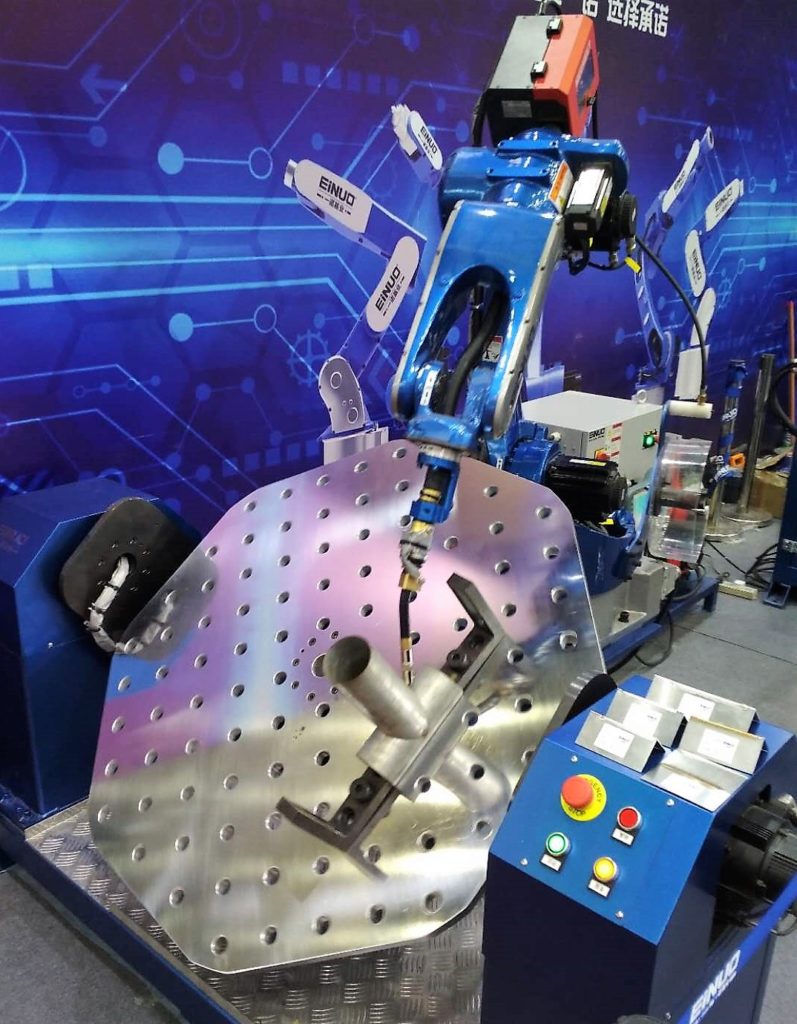

Sheet metal bending, cutting, polishing, welding, deburring, brushing is increasingly automated, provided the production quantity and the budgets allow for investments such as robot technology integration.

Another type of application showcased in hall 3 was dispensable sealing and in-place gasketing technology.

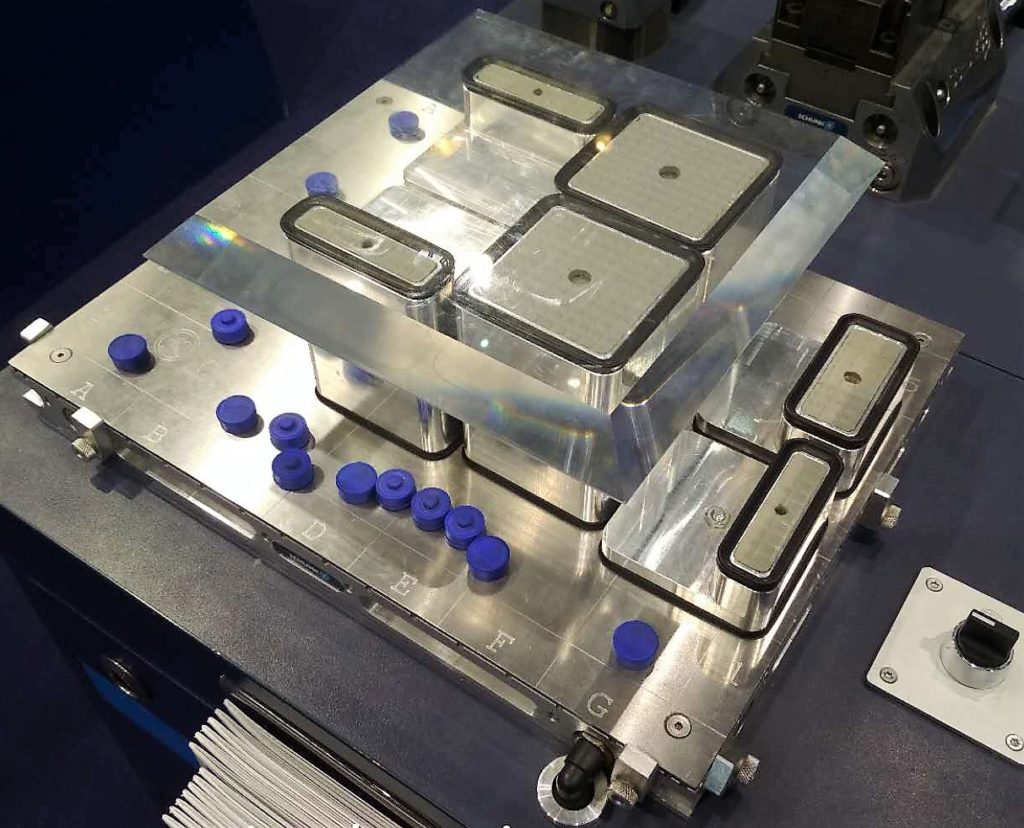

Hall 4 was mainly dedicated to die cast and injection molding tools and accessories, featuring dozens of mold makers and contract manufacturers mainly from South China, but also from Europe, North America and Japan. Correspondingly, precision machining and surface treatment technology firms were accompanying the set.

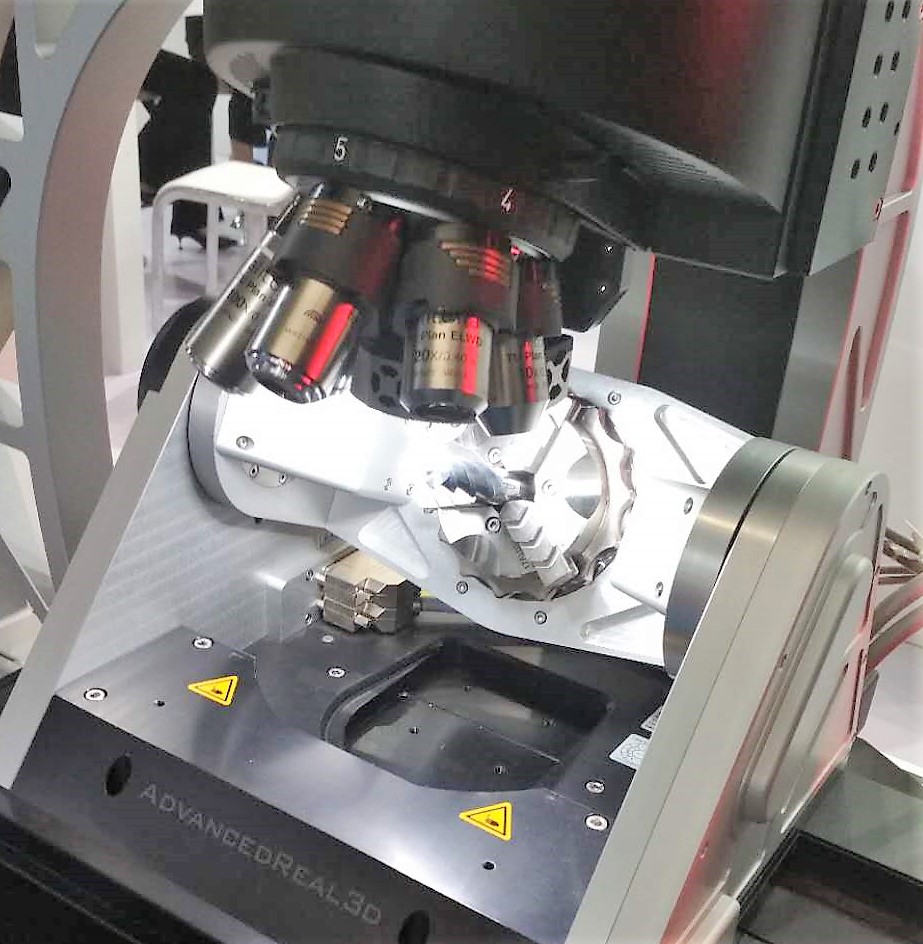

Tactile, visual and laser 3D measuring equipment was showcased in hall 5. In addition to classical form and dimension measuring and reproduction of complete component geometries in a virtual environment, surface quality control such as roughness measuring is a field that is increasingly covered by optical measuring devices. Another field that was presented here were rapid prototyping machines, mostly represented by the booming market of Fused Filament Fabrication (3D printing). Standard and custom fastener products were another product group to be found in hall 5.

While being present in every hall in combination with various fields of manufacturing, robotic applications also had their own dedicated areas in halls 6, 7 and 8. Correspondingly, automated highly dynamic motion solutions could be seen for implementations such as intelligent welding, machined metal component processing and smart packaging & logistics. Some of the most well known names here: Kawasaki, Universal Robots and Nachi Robotics.

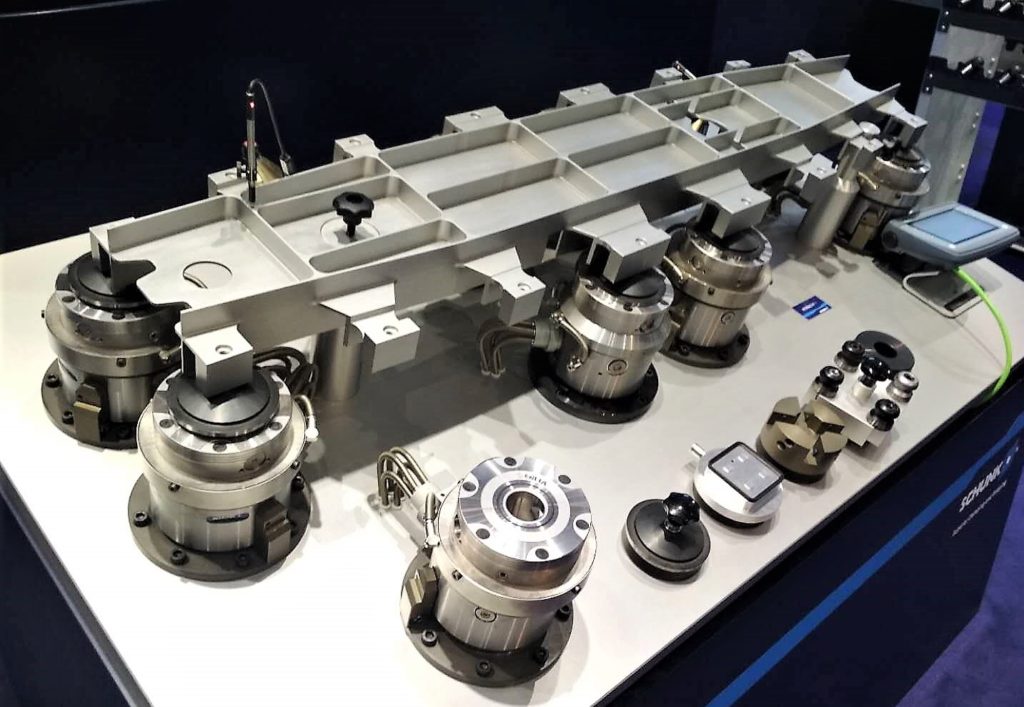

Finally, hall 9 held most of the tools, jigs and measuring equipment. Among it pneumatic and hydraulic clamping solutions, machining and measurement fixation equipment, special lathe chucks and a variety of custom cutting tools for special and high precision turning and milling jobs. In addition to many exhibitors from the host country there were firms from Germany, Sweden, the US and Japan, to name just a few.